- Tutor/s Sadasivan Iyer | Sagar Modh

- TA Parth Mehta | Aishwarya Edakhe

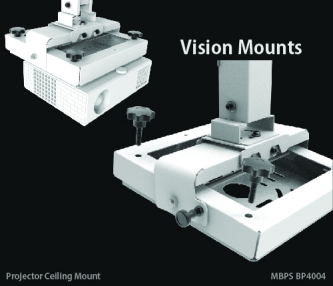

- Code BP4004

- Faculty Design

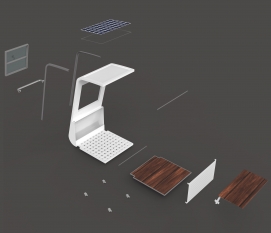

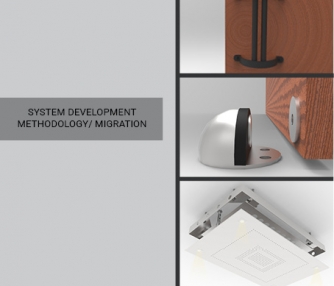

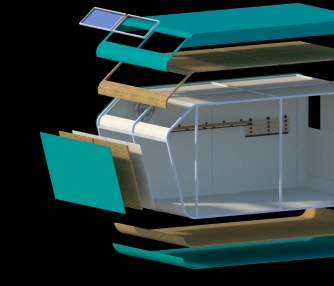

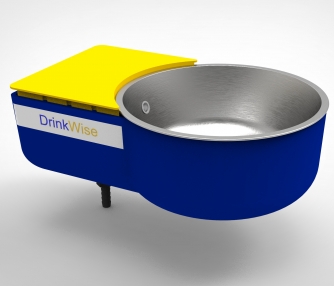

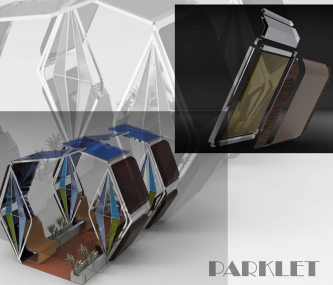

The prototype making process begins by defining the engineering/ manufacturing challenge, performance requirements, brainstorming potential solutions, and evaluating several alternatives. An engineering/ manufacturing team synthesizes this information to begin the product manufacturing process to help engineering/manufacturing teams to assess the "build ability" of the design concept, to create prototypes. By building a prototype, you should be able to determine if your chosen design solution is feasible and which aspects of your design needs special materials or further refinement. The term prototype is interchanged with the term "model," which can cause confusion. While several types of prototypes exist, for the purpose of this activity, we will make the following distinction: A model is used to demonstrate or explain how a product will look or function, a prototype is used to work out the kinks in a design or to try new ideas. Keep in mind that prototypes are unrefined versions of a future product. The manufacturing process is a critical part of product design. Once a student has developed a design for a product, she/he often creates an engineering drawing to be used by a machinist or manufacturer to create the product.